Power Factor

What is Power Factor?

Simply it is a ratio that indicate losses (KVAR) in the motor coils and inductive Loads

What is the Range of Power Factor values?

It ranges from a minimum value as 0.1 to a maximum value of 1. the lower the value of PF the higher the losses.

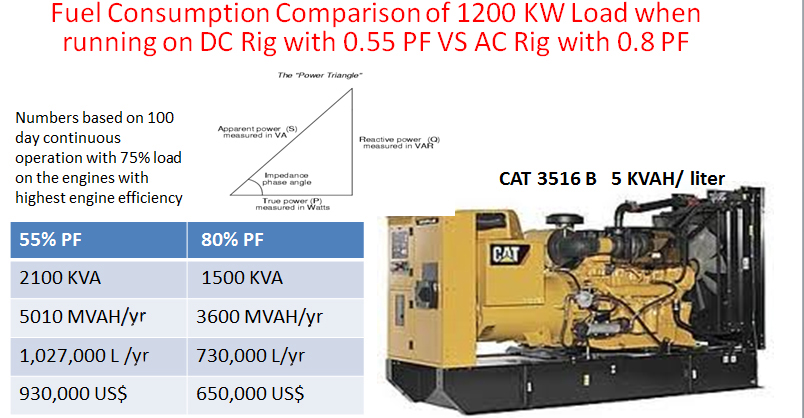

What is the Typical Range Values of Power factor in DC Rigs Vs. AC Rigs?

In DC Rigs and due to the Nature of SCR phasing down the Voltage it causes high phase angle between voltage and current resulting in low values of PF and higher losses …range of PF in DC Rigs is between 0.4 ~ 0.75 while in AC Rigs PF is never below 0.85 ~ 0.95

How to improve Power Factor in DC Rigs?

Without any added Solution , if you run your MP and DWKS at higher Strokes and RPM this will improve Power factor to the maximum of the range mentioned above (0.75)…..Example if you can always use smaller liners with higher SPM and avoid bigger liners with slow SPM ….but that is not feasible and practical and in DWKS you can never run at high rpm during Hoisting Heavy Pipes and casing ….So we will need an added Solution.

Power Factor Correction

● It is an electric panel/House which is connected across Rig Generators to monitor Power Factor and automatically increases Power Factor to desired programmed Value.

● When connected to DC rig and By setting PF value to 90% then the efficiency will be increased and rig will run like an AC rig with VFD Drives with much less Fuel consumption.

● The amount of Saving and other benefits will depend on how low the power factor goes down and the time it remains on low PF.

Proven Benefits of Power Factor correction

● Lowers fuel consumption and makes the DC rigs as efficient as AC rigs.

● No need to extra increase the size of generators in the engine package (typical engine package for DC rigs might have 50% increased generator rating over engine rating to overcome extremely low PF situations like low SPM , high pressure on Mud pumps).

● When compared in cost, the price of increased generator size to the PF correction system is almost the same which simply means we get other benefits for free (for the case of new build/upgrades or changing engine).

● Depending on drilling scenario/load, in many situations we can run with one engine less in case of PF correction is installed. Running with one engine less will surely reduce maintenance cost per year.

● Most of the modern Digital PF correction units comes with Active Harmonic filters built is so another big benefit of eliminating harmonics which will reduce electric failures and increase the expected life of drilling motors by about 35% (EPRI studies)

How to Proceed , The Financial Models

1- Own The Solution, Capital Purchase :

We as NOK quote , You evaluate and may issue a PO and pay the money and wait for the savings to happen. After Warranty period all Problems, spare parts in the System are your call.

2- Rent The Solution :

We as NOK quote , You evaluate and may issue a PO and start paying the agreed Day Rate and wait for the savings to happen. What if Rig is not working or during Move slots , you are paying rent and no savings.

3- Host the Solution and Let us become Partners :

Don’t pay upfront , Don’t spend anything on parts or maintenance of the solution …just pay us from the savings

The Scenario:

1- You Should Know your base line Diesel consumptions per well or per Month ( if you don’t know we will provide fuel meters to create the base line which You and us will agree upon)…….

2- NOK will install the Unit on the rig with the Flow meters and it will provide Tech with the unit at the beginning to teach Rig Tech on how to check its status, put it online , take it offline,…etc.

3- Based on the accumulated reading of Flow meters and the reduction made in Fuel consumption from the base line , NOK will charge 50% of the saved Fuel Monthly.

4- All Problems, Maintenance and parts to keep the unit working at all time will be NOK call.